Pasta has been a mainstay in American households for many years because it is easy to prepare and can be used in many different ways. Understanding pasta production lines becomes crucial as the demand for dried and fresh pasta grows. This article looks at what goes on behind the scenes in pasta manufacturing in America, specifically technological advancements, strategies, and undertakings involved in producing these products. The various methods of making them, materials used during manufacture, and how they affect quality and consumers’ choices will be examined. We will take you through the exciting journey of pasta making, revealing what separates American-made pasta from others around the globe.

What is Included in a Typical Pasta Production Line In the US?

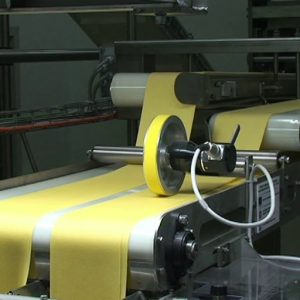

Image source: https://www.sarpna.com/

In the United States, several main parts of an ordinary pasta production line work together to guarantee efficiency and high-quality results. The ingredient preparation begins with a dough made by blending flour and water. Afterward, a dough sheeter flattens the dough to your preferred thickness. Finally, the dough goes through an extruder, which gives it its shape, such as penne, spaghetti, or fettuccine.

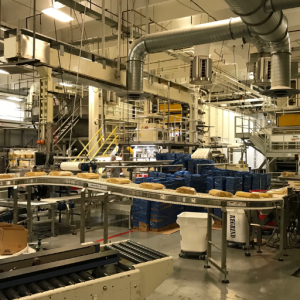

The end product is then dried in controlled environments to attain the requisite moisture content for dry pasta or packed for fresh pasta. Quality control systems continuously monitor texture, color, and moisture levels at every stage to ensure that the final product meets industry and customer expectations. Furthermore, packaging machines and labeling systems, among other things, are essential for preparing pasta for distribution purposes.

Key Elements of Dry Pasta Production Lines

Dry pasta production lines are composed of many vital components that help increase efficiency and quality. The first significant component is an ingredient handling system that enables accurate measurements and mixing of semolina and water. This is usually followed by dough mixing and kneading machines that guarantee a homogeneous mixture. The next important element is the extrusion system, which changes the dough into various pasta shapes.

The shaped pasta then goes through a process known as thermoregulated drying, where temperature and humidity are strictly controlled to remove moisture without damaging its quality. Cooling systems also ensure the pasta has cooled to the right temperature before packaging. Besides, there are QA stations throughout the production line for parameters such as color, texture, and moisture level, among others. Finally, automated packaging machines package the final product so that it remains fresh during shipment and maintains its quality.

Essential Components of Fresh Pasta Lines

Some unique components in fresh pasta production lines distinguish them from dry pasta systems. The dough mixing process is at the core of fresh pasta manufacturing, often performed by heavy-duty mixers that blend fine flour, water, and eggs to improve the texture. After mixing, the dough is commonly laid down with rollers on a conveyor belt to get the desired thickness before it can be cut into various shapes like ravioli or fettuccine.

The minimal drying after shaping helps fresh pasta retain its freshness as it is meant for immediate consumption, although it may have a short chilling period for quality preservation. Packaging systems designed specifically for fresh pasta are equally important because they include vacuum sealing, ensuring freshness is preserved, and extending shelf life. At every stage of this process, strict supervision guarantees good hygiene practices, such as frequent cleaning and sanitizing machinery to avoid contamination. In summary, fresh pasta production lines heavily balance high-quality ingredients and efficient processing techniques to provide a product that meets customers’ expectations regarding taste and freshness.

Automation in Pasta Production Lines In US

The pasta industry in the USA has experienced a significant revolution since the automation of pasta production lines, which has improved efficiency and product uniformity. Leading manufacturers are also advancing the technology to use AI-based systems and robotics to improve numerous production stages, such as mixing and forming through packaging. For example, automated systems adapt rapidly across various pasta shapes, thus reducing downtime and increasing product variety without compromising quality.

Besides, data analysis tools are increasingly being deployed to monitor equipment performance, thus streamlining operations. This technology helps predict and mitigate issues before they occur, reducing waste and improving overall flows. Consequently, there is an emerging trend for smart factories where interconnected devices communicate with each other in real-time, hence driving efficiencies and ensuring compliance with food safety standards. In sum, integration of automation into pasta production lines not only increases output levels but also improves the ability to meet consumer demands for high-quality fresh products.

How Does Pasta Production Work?

High-quality ingredients such as semolina flour and water are carefully selected to start the pasta production process. In the first step, a dough is made from these ingredients, which is then developed into a gluten structure through kneading so that the pasta can have its desired texture. The dough is then shaped using different methods like extrusion or rolling to get a specific form of pasta.

Pasta is subjected to cooking or drying upon being shaped, depending on whether it will be sold fresh or dry. Freshly produced pasta generally gets refrigerated, while dried pasta has to be completely dehydrated to ensure shelf-life stability. Eventually, modern packing materials are used for product finishing during distribution when cleanliness and efficiency are considered. The pasta’s quality, smell, and feel remain intact through this straightforward manufacturing approach, as consumers expect.

From Flour to Long-Cut Pasta

For pasta production, flour can be converted into long-cut pasta by choosing flour that is high in gluten proteins for its durum wheat flour. The dough is always stiff and made up by mixing water with flour though a process of mixing that ensures even hydration. This dough, when kneaded, strengthens the gluten, making the pasta able to retain its shape during cooking. In addition, after kneading, the dough is allowed to rest, making it easier to shape as it relaxes the gluten.

The next step involves extruding the rested dough through complex machinery to create long-cut shapes like spaghetti or fettuccine. Through forcing the dough via a die that will help in forming the final shape of the pasta and then cutting it into the required grades, they make use of an extrusion machine.. Dried long-cut pastas are dried considerably to last longer while fresh packed pastas are refrigerated on time so that they do not lose their soft texture right away.. It follows, therefore, that such a careful approach guarantees perfect consistency and quality of commercialized pasta output.

Different Pasta Shapes and Their Production

The numerous pasta shapes have all been designed to accompany various sauces and dishes. Some include penne, fusilli, and lasagna, among many others. When creating shaped pasta, the production method is usually similar to that of long-cut pasta, and it first starts with mixing high-protein durum wheat flour with water. Afterward, the dough is put into molds or dies, which are shaped differently. For instance, that penne is cut diagonally after it has emerged from a tubular die, while fusilli is made by twisting strands of pasta around a rod as they are extruded outwards. Drying is the next step after shaping so that it can be stored for long periods without getting spoiled, thereby enabling customers to have varied forms and experiences in their cooking preparations. Learning how specific designs are created makes it easier to appreciate that pasta’s versatility cannot be overemphasized; thus, one should always use appropriate pasta when making sauces.

The Role of Pasta Machinery

Efficiency and consistency are ensured by pasta machinery, which is a significant entity in pasta production. Modern pasta-producing units have embraced technology and depend on sophisticated devices such as mixers, extruders, and dryers to facilitate this process. These mixers blend water with high-protein durum wheat flour to form a consistent dough, while these dies are used to shape dough into required forms through extruders. As for dryers, they help remove any moisture from the formed pasta that could spoil it or make it go off easily. With this machinery, not only can productivity be enhanced, but also maintain control over the cooking and drying processes to meet the expectations of customers on quality and standards. Spaghetti is just one example of the numerous shapes produced by automation and technological improvements in pasta-making equipment, as well as allowing for mass production of quality products across different sizes.

What Are the Differences Between Dry Pasta and Fresh Pasta Production?

The key variance between fresh and dried pasta production is the ingredients, process flow, and times for drying. On the other hand, dry pasta is typically made with a mixture of durum wheat semolina and water, which are mixed, extruded, and then dried after the removal of moisture; in this way, it can be stored for longer. It takes several hours to carry out this drying process, and specific machines are necessary to facilitate uniform dehydration. Unlike that, fresh pasta is much softer due to the utilization of all-purpose flour plus eggs or water. This kind of food is often cooked within two or three days after being made because it has not yet been dried. Fresh pasta production also concentrates on its speed and hence involves rolling or cutting techniques that give rise to small shapes. Both types of pasta provide different culinary experiences, with dry pasta being convenient for long-term storage while fresh pasta tends to have a better-cooked texture than dried ones.

Heat Treatment in Dry Pasta Production In US

The quality and shelf life of dry pasta are influenced to a great extent by heat treatment. This usually comprises pasteurizing or pre-cooking the pasta to eliminate any possible pathogens and improve its general texture. According to industry reports, most pasta manufacturing companies use techniques like high-temperature short-time (HTST) processing, where the pasta is subjected to high temperatures for a short duration so that there is less water in it, further increasing its shelf life. The process helps maintain the pasta’s taste and improves its cooking properties, thus ensuring that the end product is safe for eating and has a good texture. Additionally, advancements in technology have led to better control of the heat treatment process, which allows manufacturers to optimize outcomes based on recipe requirements and consumer preferences.

Processes in Fresh Pasta Production In US

The first step in USA pasta production is a series of key processes guaranteeing quality and authenticity. Primarily, a blended semolina flour-water mixture (composed mainly of mixtures containing semolina flour and water) with precise moisture content is prepared from high-quality ingredients. The dough, afterward, is worked on by kneading and resting to make gluten structure develop for elasticity reasons. Then, specialized equipment allows you to roll the dough thinly to acquire the required thickness while maintaining an even texture. At this point, the rolled dough is cut into various forms, like fettuccine, lasagna sheets, or ravioli, depending on what product is made. Once shaped, fresh pasta is usually allowed to dry for a short period before it’s packed to stiffen up. This fast mode of production focuses on minimal handling to ensure pasta retains freshness and softly textured qualities, which makes it ready for immediate use or cooking.

Packaging for Dry vs. Fresh Pasta

Packaging dry and fresh pasta for different purposes based on their preservation requirements. Dry pasta has a longer shelf life and is often packed in materials like cardboard or plastic bags that are moisture-proof to shield them from humidity and pests. This type of packaging is made to last long while providing convenience for easy storage in pantries. On the contrary, moist materials like sealed plastic trays or bags are used for fresh pasta to preserve its soft texture and prevent quick drying. This kind of goods sometimes has a shorter shelf life, hence the need for refrigeration; therefore, its packing is designed to communicate clearly about expiration dates and storage instructions. Moreover, branding and labeling are important for both varieties; they help consumers identify different brands and offer information regarding ingredients used in making it, together with nutritional value and cooking details.

How to Select the Right Pasta Machinery?

When picking out pasta machinery, there are several things you need to consider for efficiency in production. Initially, decide on the amount of pasta you want to produce; high-output equipment is suitable for large-scale activities, while smaller ones may be enough for handmade products. Second, determine the type of pasta you will create because specific machines are made for different shapes and sizes. Thirdly, consider your space and how your facility is arranged; some require more floor space and utilities than others. Also important is how easy it is to operate the machine, what it takes or costs for maintenance, and whether replacement parts can be sourced. Lastly, review the manufacturer’s reputation and customer feedback so that you can be sure of trustworthy service with good quality machines.

Choosing Machinery for Dry Pasta Lines

When choosing machines for dry pasta lines, you must look at three main things: efficiency, adaptability, and technology. High-quality dry pasta machinery should be able to maintain production speeds with product integrity usually achieved through high-temperature control systems, which are often complexly monitored. This is because such machines should have the capacity to make various pasta forms without going through many transformations. Besides, suppose one goes for machines installed with the latest technology like automated systems or real-time monitoring tools. In that case, he can achieve higher efficiency and lower waste in operations. It is important to consider suppliers with strong support and service networks, as this will guarantee good performance and durability of equipment.

Machinery Options for Fresh Pasta Lines

There are three important factors to consider when considering machinery for making fresh pasta: versatility, speed, and quality control. Fresh pasta machines are mostly divided into two categories: those that mix and knead dough and extruders that create shapes out of the pasta. They also emphasize the importance of machines that allow for rapid conversion between various types of pasta to minimize downtime. Moreover, they should have built-in steamers or cookers to improve the quality of the product. Also, efficient models must concentrate on waste reduction through precise portions control and adjustable options. It is necessary to go over user experiences and expert reviews on the latest models so that you can make informed choices regarding the alignment of machinery with your production needs.

Scaling Your Production Capacity with Pasta Machinery

Pasta machinery has to be evaluated with respect to operational scalability and equipment flexibility for effective scaling of production capacity. Modern pasta production lines require modular machines that can be expanded or upgraded when needed. This implies that businesses can begin with the necessary tools and then add additional items, such as additional mixers or extruders, without necessarily overhauling the entire system.

In line with leading industry insights, investing in high-speed machines that maintain quality is important. In addition, digital technologies and automation reduce real-time monitoring by streamlining processes and enhancing output uniformity. Lastly, ensure you partner with suppliers who will provide continued technical support and spare parts so that your machinery keeps running smoothly, thus enabling scalable production further.

What Are the Common Challenges in the Pasta Production Industry?

Several common challenges face the pasta production industry, affecting efficiency and profitability. Maintaining uniform quality across batches is a significant concern, as the texture and taste of end products can differ due to variations in raw materials. Moreover, any downtime for equipment maintenance or failure may result in disrupted production plans and financial losses.

Furthermore, the industry also has issues with labor shortages and skilled workers, who are increasingly being replaced by automation and advanced machinery. Then again, the budgets for many organizations get strained because of ingredient price swings, whereas operations based on tough conformity guidelines make everything more complicated. Finally, changing consumer preferences towards healthier pasta types like gluten-free or specialty products requires innovative approaches in product development, and many processors may not be ready to take on this challenge.

Optimizing Pasta Processing In US

Manufacturers have used many leading industry practices to optimize pasta processing in the USA. First, investing in the latest machinery that increases speed and maintains quality is crucial. Additionally, automation technologies allow precise control of production parameters, making batches consistently match each other. Moreover, real-time data analytics helps monitor performance, leading to immediate correction and improved output rates.

In addition, high-quality raw materials are essential; liaising with consistent ingredient quality suppliers will improve the final product. Employee training and development programs are also critical for providing staff with the necessary skills to operate advanced equipment and respond effectively to technical challenges. Finally, regular machine maintenance reduces downtime and streamlines production processes, contributing significantly to the pasta sector’s operational efficiency.

Achieving Pasta Production In US Maximum Quality

To achieve high standards in pasta manufacturing in America, it is necessary to guarantee the highest level of quality control from raw material selection to the final product. Some leading industry websites highlight some best practices.

- Quality ingredients: Sourcing the best durum wheat and other ingredients will greatly influence the texture and taste of the pasta. Collaborating with reputable mills ensures a constant supply of high-grade semolina.

- Process Control: Precise processing methods, such as the right cooking time and temperature, are key. This ensures proper texture while avoiding overcooking, resulting in perfect al dente.

- Testing and Feedback: Continuing product testing and consumer feedback loops help identify potential areas for improvement. Novel ideas like integrating consumer sensory panels could help balance flavor and improve texture profiles based on customer preferences for this market segment.

Manufacturers would, thus, need to prioritize these strategies so that they can raise their pasta quality standards and meet consumers’ expectations, thereby boosting brand loyalty.

Frequently Asked Questions (FAQs)

Q: What are the main components of a dry pasta production line in the US?

A: In the US, the main components of a dry pasta production line typically include mixers to produce dough, extruders for shaping pasta, dryers, and packaging machinery. These components work together to ensure the efficient and high-quality production of pasta products.

Q: How does a long-cut dry pasta production line differ from a short-cut dry pasta production line?

A: A long-cut dry pasta production line is designed specifically for producing types like spaghetti and tagliatelle, whereas a short-cut dry pasta production line focuses on products like orecchiette and short pasta. The machinery, such as cutters and shakers, is tailored to handle the different shapes and lengths.

Q: Is it possible to make gluten-free pasta using these production lines?

A: Gluten-free pasta can be made using specialized equipment and specific processes. Manufacturers often use alternative flour and ingredients that do not contain gluten to produce gluten-free pasta without compromising quality.

Q: What types of fresh pasta can be produced with these lines?

A: These production lines can produce various types of fresh pasta, including ravioli, tagliatelle, cannelloni, and more. The versatility of the pasta machinery for industry allows for creating different shapes and fillings to cater to diverse market demands.

Q: What is the main purpose of an automation system equipped pasta production line?

A: The main purpose of an automation system-equipped pasta production line is to streamline production, improve efficiency, and ensure consistent quality. Automation helps reduce manual labor and increase the output rate, reaching high levels of productivity for industrial production environments.

Q: How much pasta per hour can a typical industrial production line produce?

A: A typical industrial production line can produce thousands of pounds of pasta per hour, depending on the specific machinery and production setup. High-capacity lines are designed to meet large-scale demands while maintaining quality and consistency.

Q: Can I get help redesigning my pasta plant to improve efficiency?

A: Many manufacturers and service providers offer consultancy and redesign services to help improve the efficiency of existing pasta plants. You can contact us through our contact form for more information and assistance on redesign projects.

Q: What are the application areas for a semiautomatic pasta production line?

A: Semiautomatic pasta production lines are ideal for small to medium-sized businesses that need a balance between manual intervention and automation. These lines are suitable for producing various pasta products in moderate quantities and offer flexibility in production.

Q: How does the production of fresh pasta differ from dry pasta?

A: The production of fresh pasta involves different processes and machinery compared to dry pasta. Fresh pasta often requires less drying time and has a softer texture, whereas dry pasta undergoes extensive drying for a longer shelf life. The equipped pasta production line’s main purpose is to ensure that these differences are accounted for to produce high-quality fresh or dry pasta accordingly.

Q: What kind of semolina is used in pasta production lines?

A: High-quality durum wheat semolina is typically used in pasta production lines to produce the best pasta products. This semolina type provides the gluten structure and protein content required for pasta to hold its shape and texture during and after cooking.