Over the past few years, the popularity of pasta has grown tremendously due to its adaptability and usage in various types of food. Thus, Indian pasta production has changed significantly from traditional methods to modern automatic noodle plants. This article will describe how these machines work, including their parts, the benefits of using them instead of manual labor, and information on new technologies developed recently in this field. Suppose you are an investor interested in starting your own business related to manufacturing pasta or just want to learn more about it. This post is meant for you because it contains all the necessary details for dealing with automatic noodle-making equipment in India.

What is a pasta production line?

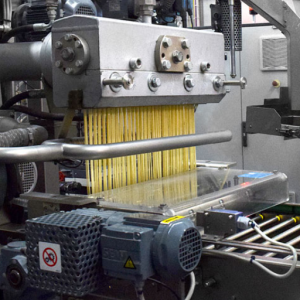

Image source: https://www.italpast.com/

A pasta production line is an arrangement of several machines connected and used to automate the pasta-making process. It includes different processes like mixing flour with water into dough, shaping the dough into various types of pasta, and drying the final product for storage. This method improves efficiency and productivity and guarantees uniformity in quality among all batches of produced pasta. Manufacturers can cut down on labor costs substantially by using a fully automated machine or automatic pasta production line, increasing their output in response to rising consumer demand for more noodles.

Components of a pasta production line

A pasta production line has several main parts, all of which play important roles in the process.

- Dough Mixer: This machine blends flour with water to create dough of consistent quality. It helps ensure that the texture and moisture content of the dough are right for making high-quality pasta.

- Extruder: The extruder shapes the pasta by forcing it through dies, which creates different types such as spaghetti, penne, or fusilli. It does this using pressure on the dough.

- Drying Machine: After shaping, excess moisture from the formed pasta is removed through a drying machine. This step is crucial for preserving shelf life and quality during storage.

- Cooling System: After drying has taken place, there must be cooling down before packaging can occur. Otherwise, packaging might cause spoilage due to condensation forming on warm items.

- Packaging Machine: Lastly, we come to packaging machines, which prepare food products for distribution purposes like vacuum sealing them up tightly while labeling containers accordingly, either bulk or retail sizes, depending upon needs required by suppliers involved here

In order for these components of an automated, efficient pasta production line to work together seamlessly, they need each other because, without one part, none would be able to function properly, thus increasing productivity levels during manufacturing processes related specifically to making noodles!

How does a pasta-making machine work?

A pasta-making machine functions by turning raw ingredients into finished spaghetti. The first step is to mix flour and water in a dough mixer until it reaches the desired consistency. After that, the mixed dough is pushed through an extruder where different types of pasta can be formed with the help of dies. This part is essential because it determines what kind of noodles will come out. Then, after being shaped, this newly formed pasta goes through a drying process, which removes moisture from it; this prevents spoilage and increases shelf life. Finally cooled noodles are packaged using packaging machines that seal and label products for shipment. Such streamlined procedures guarantee efficiency as well as quality in production.

Types of Automatic Pasta Production

- Extrusion Pasta Production: This method involves mixing the dough and shaping the pasta using an extruder. It is known for its high efficiency and ability to create many different pasta shapes. The process allows for continuous production and works well in large-scale manufacturing.

- Sheeting Pasta Production: In this technique, the dough is rolled out into thin sheets and then cut into various pasta forms like lasagna or ravioli. This method permits precise thickness control and can be used with different kinds of noodles, making it flexible enough for specialty items.

- Fresh Pasta Production: This variety has a faster procedure that mixes fresh components before molding them into shape without the long drying required in dried varieties. Specialized machinery that maintains product quality through all stages may be needed.

What are the steps in the pasta production line?

The production line takes raw ingredients to make pasta and turns them into finished products. The process starts by mixing flour with water to form a dough. After that, kneading happens, which develops gluten for texture. Once this is done, rolling out the dough and cutting it into different shapes follows. Then comes drying out the pasta so moisture content can be reduced, thus increasing the shelf life of the product. Finally, packaging takes place, after which it is ready for consumers.

Initial setup and raw material preparation

The first step in pasta manufacturing is to source high-quality raw materials, mostly flour and water. The choice of flour is vital, with durum wheat preferred because it has a high protein content and strong gluten that affects the desirable texture of the pasta. After choosing the flour, it should be stored in a cool, dry place so that its freshness can be preserved while avoiding contamination.

When everything has been prepared, accurate measurements are necessary for obtaining an ideal dough consistency. Generally speaking, this means using about 100 grams of flour to 30-35 milliliters of water, although some recipes may require different amounts depending on what type of pasta they produce and how much they want their noodles to weigh after cooking. Before mixing sifted flour and water, let stand for at least half an hour; during this time, you will find kneading easier because relaxation occurs within gluten strands.

Processing methods in a pasta processing line

Pasta processing methods are key to producing consistent and high-quality end products. The dough is extruded after the flour and water have been mixed. Different pasta shapes can be created by pushing dough through different dies during this process. After extrusion, it goes through cutting, where the pasta is cut into appropriate lengths.

Shaped pasta then moves on to a preliminary drying stage, which lowers moisture content without affecting texture. Heated air or a steam-controlled environment is typically used for drying to achieve evenness throughout the product. Lastly, dry pasta enters packaging, where care must be taken against moisture and contamination so that quality does not diminish before reaching consumers. This process blends technology with tradition efficiently, yielding superior pasta products.

Packaging and storage of dry pasta

How dry pasta is packaged plays a big role in its quality and lifespan. Usually, it’s packed in airtight bags or boxes that safeguard the product from moisture, light, and oxygen, which all contribute to loss of quality. Most commercially packaged food includes best-by dates so that buyers can monitor freshness.

To store dry pasta properly, keep it in a cool, dry place away from sunlight, like your pantry or cupboard. The original packaging should be used for storage, but if you want to reduce humidity exposure, transfer the food into an airtight container instead. Dry pasta has a long shelf life — up to two years when stored correctly — however, inspect for any signs of spoilage, such as strange smells or discoloration, before using. You will get the most out of your noodles by following these tips.

What machines are used in an automatic pasta production system?

An automatic pasta production system uses several specialized machines to produce high-quality pasta efficiently. Key machines include:

- Mixers: They blend flour and water to form the dough, ensuring that its hydration level and texture are uniform.

- Extruders: By pushing dough through molds, extruders give it different shapes.

- Cutters: These are attachments for extruders that cut off the extruded pasta into appropriate lengths.

- Dryers: Machines that circulate warm air around to evenly lower moisture content by controlling drying processes.

- Packagers: Automated systems that seal dried pasta in air-tight packaging to maintain freshness while ensuring quality.

These machines’ cooperation makes the pasta production process more efficient and maintains product integrity.

An overview of pasta extruder machines

Combining efficiency with precision, pasta extruder machines are important in producing different types of pasta. Various shapes and sizes, like spaghetti, penne, or fusilli, can be created when a dough mixture is forced through molds using this type of machinery. Single-screw and twin-screw extruders are the two main kinds; however, twin-screw ones are preferred because they can work with more types of ingredients and yield a better quality final product consistently. Dough mixing within twin-screw extrusion occurs better than single screws, which leads to improvements in taste and texture. Furthermore, modern-day extrusion equipment has state-of-the-art temperature control features enabling optimal cooking/drying conditions, thus improving end-product quality. Due to its ability for large-scale manufacture across many recipes, both industrial & artisanal companies rely on these valuable machines during their production processes.

The role of processing machines in pasta production

Processing machines are the starting point of making pasta. It helps mix, knead, and cut dough to meet specific standards for texture and quality throughout its entire form. Once prepared, the dough can be shaped into different pasta types using an extruder (see above). After extrusion, dryers remove moisture from the product by applying controlled heat and airflow, which is important for extending shelf life and preventing spoilage. Lastly, packaging machines close up the product to keep it fresh during transport/storage. These processing machines make pasta production more efficient and ensure that what consumers taste is delicious!

Functionality of drying in the dry pasta production line

Drying is a key step in making pasta since it significantly impacts the pasta’s quality, shelf-life, and cooking properties. The main aim of drying is to decrease moisture in pasta to levels that prevent the growth of microorganisms, thus improving stability. Well-executed drying guarantees structural integrity while preventing excessive brittleness in dried spaghetti products. This usually involves controlled temperature and airflow, which uniformly removes moisture without exposing them to too much heat and can alter their texture or flavor. Moreover, optimal conditions during this process assist the development of desired al dente when cooked as well as allow better rehydration during preparation for a consistent eating experience. All in all, high-quality dry pasta meeting industry standards and consumer expectations cannot be produced without the critical step of drying involved in production lines.

Why is India becoming a hub for pasta and macaroni production?

With the growing demand for convenience foods among a rapidly urbanizing population, more and more people in India are eating pasta. This is made possible by improved production efficiency and quality and technological advancements that have made it easier to manufacture macaroni. Furthermore, the support from the government in terms of incentives given to food processing industries within the country, plus infrastructure development, will boost this sector even further. Due to its diverse agrarian environment, India can easily provide all necessary materials, such as wheat used in making noodles, which should be available throughout the year. Consequently, several factors make India suitable for significant expansion within its pasta market, becoming a hub for macaroni production globally.

Advantages of setting up a pasta plant in India

- Cost-Effective Manufacturing: Lower wages and raw materials in India minimize overhead costs. This pricing strategy allows for greater flexibility in the price of pasta products while still being profitable.

- Access to Diverse Markets: A pasta plant in India will tap into a fast-growing consumer market. The rise in urbanization and shifting diets mean that you can cater to many segments, from health-conscious eaters to those who want convenient meals.

- Government Support and Initiatives: The Indian government supports food processing industries through various incentives, grants, and infrastructure investments. Such backing creates an enabling environment for foreign direct investment (FDI), which is good news for pasta makers looking to enter this country’s market.

- Technological Developments: Modernization trends have increased production efficiency and raised overall product quality. Advanced machinery ensures consistent output standards that meet international requirements are maintained throughout production processes.

-

Sustainable Practices: Awareness about sustainability is growing among consumers both locally and globally, thus giving Indian firms involved in making different types of noodles an opportunity not only to use green methods but also package their goods sustainably so they appeal more widely across borders where there’s concern over climate change impacts on our planet’s future survival prospects.

Insights from manufacturers from Noida

The proximity of major transport hubs such as roads and airports has made it easy for businesses in Noida to work efficiently, thus ensuring that products are delivered on time. Also, the city’s infrastructure provides firms access to vital services, including logistics and supply chain management. Furthermore, manufacturers based there point out that they can partner with local schools, enhancing creativity while creating a skilled workforce suited for various industries. Lastly, the community’s emphasis on sustainability and its adoption of technology consistent with global best practices makes Noida competitive enough in the pasta industry.

Market potential and leading manufacturers and exporters in India

The Indian pasta market has shown a lot of potential for growth due to the changing preferences of consumers and the increasing popularity of Italian food. Recent research suggests that this industry is set to grow at more than 10% CAGR in the next few years. Some leading manufacturers include Patanjali Ayurved, which uses traditional ingredients, and ITC, which offers innovative products with premium quality. Other significant players are Maggie Pasta, a household name in India, and the Sunfeast brand that targets the instant pasta growing segment. These exporters are meeting international demand by following global standards to take a larger share in North American or European markets where there is still room for expansion. Health consciousness combined with convenience has attracted different groups of customers; thus, these companies have invested heavily in such marketing strategies.

Frequently Asked Questions (FAQs)

Q: What is a fully automatic pasta production machine?

A: A fully automatic pasta production machine is a type of food processing equipment designed to produce various types of pasta, from short-cut pasta to long-cut pasta, with minimal manual intervention. These machines often include several stages, such as mixing, kneading, extrusion, cutting, and drying, all controlled by a central system for efficiency and consistency.

Q: How does a macaroni pasta-making machine work?

A: A macaroni pasta-making machine mixes raw ingredients like flour and water to create dough, which is then extruded through a die to shape the pasta into macaroni. The process includes mixing, kneading, extrusion through a specific die, cutting, and drying to create the final product.

Q: What are the benefits of using a high-production pasta-making machine?

A: High-production pasta-making machines offer several benefits, including increased efficiency, consistent quality, and the ability to produce large quantities of pasta in a shorter time. These machines are ideal for industrial pasta processing and packaging and can handle various pasta shapes and sizes, from special shapes to traditional short pasta.

Q: Can these machines make gluten-free pasta?

A: Many fully automatic pasta production machines can be adapted to produce gluten-free pasta. This involves using gluten-free flour and potentially adjusting the production process to ensure the texture and quality of the pasta meet the required standards for gluten-free products.

Q: Are there machines specifically for making vermicelli?

A: Yes, there are vermicelli machines specifically designed to manufacture vermicelli. These machines handle the entire production process, from mixing and kneading the dough to extruding and drying the vermicelli, ensuring consistent quality and efficiency.

Q: What types of pasta can be made with these machines?

A: These machines can produce a wide variety of pasta types, including short-cut pasta, long-cut pasta, special-shaped pasta, and even noodles. Their versatility allows for customization in terms of pasta shape and size.

Q: Who are India’s leading manufacturers and exporters of industrial pasta processing machinery?

A: India is home to several leading manufacturers and exporters of industrial pasta processing machinery. Companies such as those based in Noida specialize in providing a range of equipment for the pasta production industry, from extrusion machines to full automation pasta processing lines specifically designed for high efficiency and quality.

Q: What is involved in setting up a pasta-making plant?

A: Setting up a pasta-making plant involves several steps, including selecting the right machinery based on production needs, ensuring proper installation and setup of equipment, and establishing a production process that includes mixing, kneading, extrusion, cutting, drying, and packaging. Additionally, considerations such as sourcing raw materials, quality control, and compliance with food safety standards are crucial.

Q: What role does a kurkure extruder play in pasta production?

A: While a kurkure extruder is typically used to produce snack foods like Kurkure, its technology can be adapted to produce pasta in specific contexts. However, its primary role remains extruding crispy snack products, not pasta.

Q: What makes Noida a significant hub for pasta machine manufacturing?

A: Noida is a significant hub for pasta machine manufacturing due to its concentration of skilled technicians, advanced machinery options, and established infrastructure for industrial food processing equipment. The city is home to some of the largest manufacturers of pasta processing machinery, making it a key player in both the national and international markets.