In today’s fast-paced world, the demand for mass-produced food that does not compromise on quality has never been higher. One particular area of focus is the production of pasta, a staple in many diets around the globe. As consumer expectations continue to rise, industrial pasta machines have become an essential asset for manufacturers aiming for efficiency, consistency, and scale. This blog will delve into the transformative role these machines play in high-volume pasta production, exploring their advanced capabilities, the technology behind them, and the benefits they bring to large-scale operations. Whether you are a seasoned professional in the food manufacturing industry or simply curious about the mechanics behind your favourite pasta dishes, this article will provide valuable insights into the modern marvels of pasta production.

Choosing the Best Pasta Machine for Industrial Applications

What to Look for in Industrial Pasta Machines

When selecting an industrial pasta machine, a number of factors need to be considered. These include:

- Capacity and Throughput: The ability of the machine to produce massive amounts is important. You should go for machines that can process a large amount of pasta per hour depending on your production needs. For instance, some top-tier machines can produce up to 500-1000 Kg of pasta per hour.

- Versatility: The type of pasta it can handle. For example, some machines are design with several forming head units that are capable of producing different types of pasta shapes such as spaghetti, penne or much more complex shapes like ravioli or tortellini; this will help you meet the diverse customer demands.

- Automation and Control Systems: With programmable logic controllers (PLCs), which is also known as automated control system, the user interface enables precise control over the process parameters such as mixing speed, kneading time and extrusion temperature during production. This way consistency is achieved while at same time minimizing manual inputs.

- Material Quality and Durability: Ensure that the machine is made from high quality materials such as stainless steel which resists corrosion and guarantees hygiene. Thus, durability takes center stage for smooth continuous operation.

- Energy Efficiency: Reducing operational costs can be achieved by using energy-efficient models which have optimized energy consumption rates indicated by specific certifications or energy audits done on them.

- Hygiene and Ease of Cleaning: Food processing calls for strict adherence to cleanliness standards; thus any part in contact with food must be easy to remove for cleaning purpose so as to avoid contamination possibilities.

- Cooling and Drying Systems: After extruding out the dough it is cooled down quickly through these systems giving it maximum shelf life within minutes before being packed into an airtight containers.

- Safety Features: Mechanisms put in place within the machine include emergency stop buttons, protective guards, and the ability of the machine to comply with industrial safety standards for operator protection.

- Technical Support and Maintenance: Efficient technical support as well as availability of spare parts is important. This has been found to be the best way that manufacturers use to reduce downtime in the event of system failures.

- Cost and Return on Investment (ROI): Nevertheless, when looking at these machines’ value in long term perspective they should not only focus on initial costs. These include among other things operating expenses such as maintenance costs, energy savings and possible increase in production output.

By giving priority to these technical as well as functional considerations; companies can select industrial pasta machines that meet their goals without compromising quality and efficiency.

Comparison between Fresh Pasta Machines & Dry Pasta Extruders

However, comparing fresh pasta machines with dry pasta extruders requires looking at several issues such as type of pasta produced, process used and specific technical parameters for each machine.

Type of Pasta Produced:

- Fresh Pasta Machines: Fresh pasta making equipment is good for producing fresh pasta which has higher moisture content and therefore results into a soft texture. The shelf life of fresh pasta is also limited requiring refrigeration.

- Dry Pasta Extruders: On the other hand, dry extruders produce low-moisture content dried pastas with much longer shelf life hence ones that are preserved without refrigeration thus hard during boiling compared to fresh ones when cooking takes a longer period of time.

Production Process:

- Fresh Pasta Machines: For example, ingredients are mixed together before being kneaded into dough from which it is then extruded using such apparatuses. Other rollers may be included on certain models which help flatten the dough so that it can be cut into different forms.

- Extruder Machines for Dry Pasta: among other things, these machines also have integrated drying systems that remove moisture to make pasta stable in terms of packaging and storage.

Capacity and Output:

- Fresh Pasta Machines: Typically have a lower production capacity, around 10-100 kg per hour.

- Dry Pasta Extruders: Higher production capacity, ranging from 150-500 kg per hour, suitable for large-scale production.

Energy Consumption:

- Fresh Pasta Machines: Generally consume less energy due to the absence of drying systems.

- Dry Pasta Extruders: Higher energy consumption due to the additional drying process.

Components and Materials:

- Fresh Pasta Machines: Often feature stainless steel components for easy cleaning and compliance with hygiene standards.

- Dry Pasta Extruders: Include robust drying systems, cooling mechanisms, and high-performance extrusion components.

Hygiene and Cleaning:

- Both types should have easily disassembled parts that allow thorough cleaning; but fresh pasta machines require more frequent cleaning as their products contain more moisture contents than dry ones do.

Cost and Return on Investment (ROI):

- Initial Costs: Fresh pasta machines generally have a lower initial cost compared to dry pasta extruders.

- Operational Costs: Dry pasta extruders may incur higher operational costs due to energy consumption for drying, but offer a longer shelf life product, which can justify the investment over time.

By analyzing the differences in type of pasta produced, manufacturing processes involved in it as well as technical parameters producers are able to decide what machine would best suit their production requirements and business goals among others.

The Importance of Capacity and Efficiency in Pasta Production

In the world of pasta production, capacity and efficiency are paramount factors that significantly influence profitability and product quality. High-capacity machines enable producers to meet large-scale demand thereby reducing the need for frequent production cycles thus lowering operational costs. Efficiency in making plain paste is not only about speed or volume but also refers to consistent quality of output. Efficient machinery reduces waste, maintains uniformity in the appearance of pasta shapes and their sizes, as well as facilitates drying of dry paste (thus improving its energy use). Ultimately, investing in high-capacity and efficient pasta production equipment is a must for manufacturers seeking to scale up their businesses, meet market needs and maximize their return on investment (ROI).

Exploring the Different Types of Pasta Machines

Dry Pasta Extrusion Machines and How They Function

The way the dry pasta extrusion machines operate is through forcing dough through die to achieve various pasta shapes. It starts with mixing semolina or durum wheat flour and water into dough. This mixture is then fed into the extruder, where the screw mechanism pushes it out through dies. The type of die being used determines the shape of the desired pasta giving common examples such as spaghetti, penne or fusilli.

Key considerations in dry pasta extrusion:

- Mixing Speed and Duration: Homogeneity of dough has to be ensured within certain ranges so that undermixing or over mixing is avoided.

- Extrusion Pressure: High force is required for forcing the dough through die which may be measured in bar or psi units. Consistent extrusion pressure maintains continuity in pasta shaping.

- Screw Speed: Screw speed varies depending on RPM (revolutions per minute) that controls rate of pasta extrusion and texture.

- Die Temperature: Controlling temperature at die by using sensor systems prevents too much heating of dough or drying it excessively.

- Moisture Content: To attain suitable texture and consistency of desired paste, moisture content should be managed precisely as required by each recipe for different pastas.

- Drying Temperature and Duration: Moisture levels in pasta can be lowered by subjecting it to recommended temperatures during drying process to ensure longer shelf life. These should however vary depending on type to prevent breaking or brittleness.

Fresh Pasta Sheeters and Cutters- Tools for Variation

Fresh Pasta Sheeters are cutters are essential tools found in any kitchen if they intend making varied types of traditional Italian pastas. These machines simplify rolling & cutting process for precise thickness as well as uniform shapes after cutting. Sheeters achieve this by pressing dough through rollers that can be adjusted to different levels of thickness for creation of lasagne sheets, tagliatelle and even ravioli dough so thin like paper. On the other hand, cutters among them have various blade attachments design to form different pasta shapes such as fettuccine pappardelle and farfalle which is a butterfly shape. Thus, acquiring a good quality pasta sheeter and cutter will make pasta making more efficient as well create professional level results that makes your fresh pasta dishes unique.

Specialized Machines for Filled Pasta such as Ravioli and Tortellini

Specialized machines for filled pasta such as ravioli or tortellini are designed specifically for these delicate types of pastas which require filling and shaping processes. Usually, these come with automated systems integrated into one machine that does all rolling, filling, sealing on top of cutting off process during the production operation. For example the ravioli machine incorporates two dough sheets onto which it dispenses the exact amount of filling required before sealing them together after which it cuts uniform pieces from the sealed sheets. However tortellini machine operates along similar lines but is suited for folding & shaping the dough into a distinctive ring-like format.

Keeping the balance of the pasta against its filling enables it to have an ideal taste and texture. Moreover, automating eliminates laborious processes thus making it possible for production of filled pasta in both small scale artisanal kitchens and large scale industries.

Increasing Production Efficiency with Automatic Pasta Machines

How Advanced Technologies and Integrated Systems Streamline the Process of Pasta Production

In pasta production, automatic features streamline this process through advanced technologies combined with integrated systems. Firstly, there are automatic dough mixers and kneaders that control precisely the rate of ingredients used giving consistent dough quality every time. Additionally, there are extruders having programmable settings that can produce several types of pastas with minimum human intervention which enhances versatility and efficiency.

More so, modern sensors and monitoring systems optimize the process by keeping ideal environmental conditions like humidity and temperature that are very important for dough texture and drying. Another feature is high speed cutters as well as dies which automatically change between different pasta types, thereby saving on time and reducing error rates.

Additionally, automated drying systems control exactly drying times and temperatures preventing over-drying or under-drying for uniform feel as well as extended shelf life. Finally, packaging machines also have an automatic weighing feature along with sealing to facilitate the last step in processing where strict weight as well as quality standards should be adhered to for each package.

This makes pasta manufacturing more efficient and scalable both for small-scale operations as well as large-scale ones since automation helps in reducing labor costs; waste generation is minimized while it enhances output.

From Dough to Dried: Integrating Continuous Pasta Dryers and Coolers

Integrating continuous dryers encompasses synchronization of a number of crucial elements necessary for effective drying procedure. Conveyor systems in continuous dryers take pasta through a sequence of temperature/humidity zones controlled within very narrow limits so that no cracks or other textural defects develop during drying. This means that various pasta types including spaghetti penne or fusilli can be dried differently.

Cooling is a key operation in the line because it reduces the temperature gradually after drying making sure that its taste will not deteriorate. The most up-to-date cooling systems use airflow regulation plus temperature controls to keep ideal conditions while efficiently lowering down temperatures under control. Furthermore, modern dryers and coolers are equipped with automated sensors and control systems that are capable of adjusting parameters in real time based on feedback thus improving quality and reducing energy use.

These continuous systems facilitate smooth transition from dough to dried pasta thereby significantly increasing throughput while retaining the high level of quality. Consequently, such automation minimizes human involvement, speeds up production cycle and reduces energy consumption in accord with sustainable manufacturing principles.

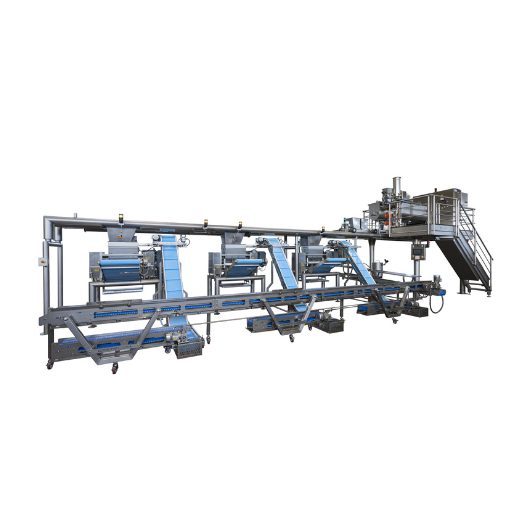

Maximizing Output with Multi-functional Pasta Lines

Multifunctional pasta lines have been designed to increase output by incorporating new technologies as well as flexible production capacities. They encompass several stages of pasta making process – mixing, extrusion, drying and packaging—within a single integrated system. These lines can quickly shift different shapes or sizes of pasta using cutting-edge automation minimizing downtime between operations thereby increasing operational efficiency.

Advanced sensors together plus control systems always keep an eye on what is going on in terms of temperature, humidity or pressure so that product quality remains uniform while resources get used optimally. Another important advantage is that modular design allows multi-functional pasta line to be easily scaled up or customized to suit any particular situation during the production process.

The manufacturers can improve their capacity by installing these advanced systems, minimize waste and enhance the overall quality of products largely through this approach. Thus it becomes possible not only to increase throughput but also achieve sustainability objectives hence purchasing multifunctional pasta lines becomes a necessity for producers who want to be competitive within this segment.

Advanced Solutions for Pasta Pre-drying and Pasteurization

Enhancing the Quality of Pasta by Pre-drying

Freshly extruded pasta has to be dehydrated before final drying takes place and pre-drying performs this as an initial step. This phase is crucial in stabilizing the structure of pasta so as to withstand deformation and promote uniform drying. It also helps in reducing surface cracking and maintaining the desired texture and elasticity of the pasta. Moreover, it facilitates better control over drying process thus minimizing energy consumption and attaining more consistencies across all batches. Therefore, optimizing the pre-drying stage helps manufacturers achieve high-quality pasta with improved cooking characteristics that meet consumer expectations and industry standards.

Pasteurization: A Safety Measure for Pasta Production

Pasteurization represents a pivotal procedure in securing food safety when it comes to pasta manufacture since it guarantees eradication of harmful elements such as microorganisms that bring about food poisoning. In most cases, pasteurization involves heating pasta at a given temperature for some time while preserving its nutrient content and quality. Therefore, this method is a way of increasing shelf life without compromising flavor, texture or appearance of the product. Through inclusion of pasteurisation into their production lines, producers are able to ensure that their products meet stringent health requirements thereby giving them confidence among consumers who may want safe foods.

Static Dryers vs Continuous Dryers: Which is Best?

Therefore various parameters should be taken into account when deciding on whether static dryers or continuous ones would be used for making pastas such as throughput, energy efficiency and flexibility concerning operations.

Static Dryers:

Static dryers are operated according to batch processing principles whereby pasta is loaded onto dryer placed at rest before undergoing controlled drying cycle; achieved by means of precise monitoring over temperature/humidity/air flow rates (Pedro 1). As compared to other technologies, static dryers tend to provide consistently good quality product (Pedro 2). They are also suitable for smaller quantities because they can maintain the shape and texture of the product.

Technical Parameters:

- Temperature Range: Normally 50°C to 80°C

- Drying Time: Between 7 and 20 hours, depending on pasta type and thickness

- Energy Consumption: Moderate to high – depends on cycle duration and temperature settings

- Capacity: Typically less than a few tonnes per batch; designed for smaller-scale operations

Continuous Dryers:

These types of dryers pass pasta through drying tunnel under controlled conditions at different stages (Pedro 1). Continuous dryers are highly efficient in large scale production with faster rates of drying time. Due to their automated nature, continuous dryers save significantly the cost of wages as well as energy consumption.

Technical Parameters:

- Temperature Range: Generally between 60°C to 100°C

- Throughput: Capable of handling large quantities, often more than several tonnes per hour

- Drying Time: Rapid, usually one to four hours depending on the system design

- Energy Consumption: Due to continuous operation, more energy-efficient per unit product since energy is optimized.

Comparative Considerations:

- Production Volume: Static dryers are best for small runs, specialty pastas or artisanal products while continuous ones would be great for mass production lines.

- Product Variety: Static dryers can handle various shapes and sizes that require specific process conditions whereas continuous ones cater for uniform batches where manual adjustments are not needed.

- Energy Efficiency:Continuous dryers are more energy efficient in high volume production while static dryers use more energy, especially during longer drying cycles.

- Space and Infrastructure:Continuous dryers generally require more infrastructure and space and thus become a bigger capital investment; however, their efficiency and capacity makes them provide better returns on investment in the long-term.

The scale of production, the type of pasta being produced and the available infrastructure determine which drying method is best suited for any given situation.

The Future of Pasta Production: Automatic and Artisanal Combined

Introducing Manual Techniques in High Volume Pasta Production

To introduce manual techniques into high-volume pasta production, I emphasize the integration of traditional craftsmanship with modern technology. Blending artisanal methods like hand-rolling and shaping some specific types of pasta into automated systems ensures that the end product maintains its homemade nature and texture. Furthermore, I engage proficient craftsmen for overseeing and refining these aspects within the production line, thereby ensuring originality and satisfying demand for premium pasta experiences. This way of doing things does not only conserve the core of conventional pasta making, but also takes advantage of the efficiency and practicality of advanced machines to achieve quality with quantity.

The Emergence Of Artisanal Pasta In Industrial Contexts

The emergence of artisanal pasta in industrial contexts has been fueled by an increasing consumer preference for quality and authenticity. By integrating traditional means of producing pasta into mass manufacturing, I guarantee that my products retain their full taste as well as their strong flavors which are preferred by a particular kind of customers who know what they want. This technique involves use good ingredients as well as procedures such as slow drying or extrusion through bronze die usually associated with handmade pasta. When combined with modern machinery’s efficiency, these ways enable me to produce healthy pastas while scaling up to large scale production requirements. It is a method that meets both current market demands and bridges the gap between handmade excellence and productive capability.

Nurturing The Transition To More Sustainable Methods Of Pasta Making

Nurturing the transition to more sustainable methods of making pasta involves a diverse approach comprising reducing carbon footprints, lessening water usage and using eco-friendly packaging. My key policy is nationwide sourcing organic ingredients thus lowering transportation emissions while promoting sustainable agriculture practices. The use solar power on the roofs coupled with wind turbines within our plants greatly reduces non-renewable energy consumption levels thereat. Additionally, I prefer water conserving mechanisms like closed loop processes that provide opportunities for recycling and reusing water in a way that is efficient. Innovations in packaging are also important, focusing on biodegradable or recyclable materials for minimizing environmental effects. By introducing all these practices, I am not only meeting the demands of environmentally conscious customers but also making a constructive contribution to the nature.

Reference sources

1. Online Article: “The Benefits of Industrial Pasta Machines in High-Volume Production” – Food Processing Technology

URL: Food Processing Technology Summary: This article from Food Processing Technology dives into the advantages of using industrial pasta machines for large-scale production. It covers various aspects such as efficiency, consistency, and cost-effectiveness. The piece also includes interviews with industry experts and case studies from prominent pasta manufacturers, making it a comprehensive resource for those interested in the operational benefits and real-world applications of these machines.

2. Academic Journal: “Advancements in Pasta Manufacturing: A Review of Industrial Machinery” – Journal of Food Engineering

URL: Journal of Food Engineering Summary: Published in the renowned Journal of Food Engineering, this peer-reviewed article explores the latest technological advancements in pasta manufacturing. It provides an in-depth analysis of different types of industrial pasta machines, their engineering principles, and their impact on production quality and volume. The paper also compares traditional methods with modern machinery, offering readers a scientifically sound perspective on the evolution of pasta production technologies.

3. Manufacturer Website: “High-Volume Pasta Production Solutions” – Buhler Group

URL: Buhler Group Summary: The Buhler Group’s website is a valuable resource for learning about the latest industrial pasta machines designed for high-volume production. It features detailed product descriptions, technical specifications, and customer testimonials. Additionally, the site offers insights into the company’s innovative approaches to improving production efficiency and product quality through advanced machinery. This source is particularly useful for understanding the practical capabilities and features of state-of-the-art pasta manufacturing equipment.

Frequently Asked Questions (FAQs)

Q: What pasta can be made through industrial pasta manufacturing machines?

A: Industrial pasta manufacturing machines are capable of producing a wide range of pasta types including short ones like penne, long kinds such as spaghetti, special ones which have shapes like fusilli or farfalle, stuffed types including ravioli, cappelletti and gnocchi and also regional variations. These equipment could be customized to meet the specific requirements for making traditional as well as innovative designs for pastas.

Q: How do pasta sheeter and pasta press machines enhance pasta quality in high-volume production?

A: Pasta sheeter and press machines are vital in the manufacture of high-quality pasta under mass-production conditions. The sheeter machine spreads the dough equally to a given thickness thus achieving consistent texture while the press machine molds it into desired shapes with accuracy. This helps produce pastas that look similar with regards to coloration, cooking characteristics, etc.

Q: Can industrial pasta machines support the production of both dried and fresh pasta?

A: Yes, industrial pasta machines can produce both dried and fresh pastas. Machines with dryers or pasteurizers can make both instant consumption type of products or dried pastas with longer shelf lives. Such flexibility is one reason why they are preferred by manufacturers who want to meet different market demands.

Q: What role do pasteurizers play in pasta factories using industrial pasta machines?

A: Pasteurizers play an essential part in any modern factory that deals with fresh food especially precooked ready meals or those based on fresh noodles. They ensure that all harmful bacteria have been destroyed through heat treatment enabling people to consume this product without fear by prolonging its life span . Sterilization process is very important since it guarantees safety and enhances the quality of these items before packaging.

Q: How do forming machines contribute to variety of produced shapes in a given plant?

A: Forming machines have an integral role when it comes to producing many pasta shapes in a factory. These can be altered to provide diverse shapes; spaghetti and penne being examples of traditional forms, while others include cappelletti, gnocchi or special kinds of pastas. This way the producers are able to diversify their range of products focusing on specific market needs.

Q: What are the benefits of using steam cookers in the production of special pasta types?

A: Steamers have multiple advantages during production of these niche products highlighted especially for precooked or ready meals whereby they ensure even cooking with accurate temperature control that helps them achieve desired texture while also preserving the nutritional composition’s integrity. By making special pasta types such as pre-cooked lasagne sheets or dumplings, steam cookers produce a premium product consistently that meets consumer expectations when it comes to artisanal and commercial pasta productions.