In the modern world of food manufacturing, efficiency and consistency are key. This is particularly true in the pasta industry, where the demand for high-quality macaroni is ever-growing. This comprehensive guide aims to unlock the secrets behind the automatic macaroni production line, providing a thorough overview for enthusiasts and professionals alike. From understanding the machinery and processes to exploring the benefits of automation, this article will delve into every aspect of production. Whether you’re new to the industry or a seasoned manufacturer, this guide will offer valuable insights and essential knowledge to help you navigate the intricate world of macaroni production.

Pasta Making: The First Step in Macaroni Production

The Right Raw Material for Quality Pasta Production

The best raw materials are the foundation upon which high quality pasta is made. Durum wheat semolina is primarily used because of its high protein content and gluten strength, which give pasta its firm texture and cooking resistance. This semolina must be milled uniformly to ensure uniform hydration and extrusion properties of the dough. Additionally, impurity-free water with balanced mineral content will enhance the dough consistency when a company utilize it in preparing their pasta. Moreover, stringent standards for premium pasta production require regular quality checks and sourcing from reliable suppliers.

Understanding The Role played By Extruders In Making Of Pasta

Extruders are key players in making of pasta as they fundamentally shape it from a dough to its final form. The extrusion process commences by mixing selected raw materials into a homogenous dough. When passed through dies by being pushed out of extruder’s screw mechanism; this dough forms different shapes of pastas can be produced by extruder machines.. Through these screw mechanisms, not only pressure is kept steady but also uniformity in texture and density is maintained throughout the pasta. For instance, if the temperature within an extruder deviates from normal values, it affects viscosity level of that particular paste hence lowering its overall quality. Besides being versatile enough to produce many types ranging from macaroni to spaghetti using one machine, modern extruders are efficient enough to remain productive (and precise) at all times even when doing such tasks as creating penne or fusilli shapes.

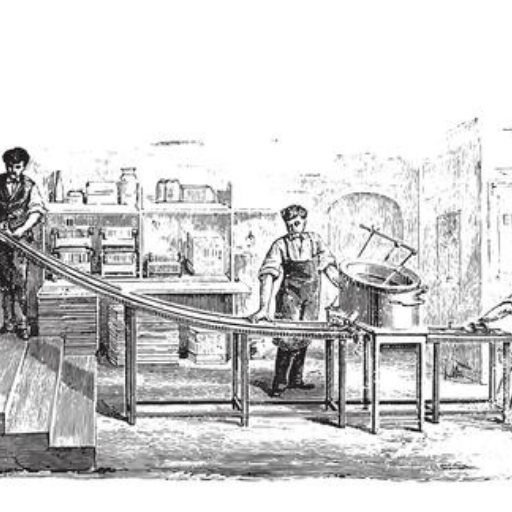

Transition From Manual To Automatic Pasta Making Machines

From manual to automatic pasta making machines indicates a significant milestone in manufacturing process driven by increased efficiency demands while achieving consistency simultaneously . Historically, skilled artisans crafted pasta manually using intensive labor methods. However, rolling kneading or cutting was time consuming with variations among them leading to inconsistent texture and quality.

With the advent of automatic pasta making machines everything has changed since the traditional way of doing things has completely been turned around. It is the responsibility of these machines to knead and shape pasta as well as dry it without any slight deviation from standard procedures. Instead, one is able to get control over ingredient ratios, dough consistency, and cooking characteristics that result in a superlative end product via automation.

Moreover, modern automatic machines integrate advanced technologies such as computer controls and sensors to further streamline operations and improve product quality. By this way, production lines are so efficient that even when they are at high capacity; the pasta remains intact. Automation has allowed for not just an increase in output but also maintenance of exacting production standards during pasta manufacturing.

Fully Automated Pasta Production Line: Efficiency Redefined

To Standardize and Automate Pasta Making

Automating pasta production entails using automatic machines to manage all the processes. Mixing the ingredients, shaping as well as drying the pasta dough are handled by these equipment. There is always an assurance of consistent quality and texture due to this. These days’ modern automatic pasta making lines have adopted some latest technologies like programmable logic controllers (PLCs) and sensors which can closely monitor variables such as temperature, humidity and dough consistency. This minimizes human error hence increasing efficiency too. These machines also allow for continuous operation reducing downtime while maximizing on output through ensuring minimal interruptions in production process thus improving performance at a constant rate. Automatic machines regulate every step that takes place when processing pasta, therefore ensuring that each brew meets rigorous quality standards required in enhancing productivity and keeping product uniformity.

How Fully Automated Lines Affects Pasta Quality And Consistency

Pasta products have become more consistent with improved quality as fully automated production lines came in place. In particular, such lines are fitted with accurate controls and advanced sensors that help them maintain perfect conditions throughout the entire manufacturing process as a whole. The technical aspects covered include:

- Ingredient Mixing: For a uniform end result in making the dough, automatic mixers handle flour ,water plus additives mixing.PLCs are important here because they help to control mix times or speeds.

- Dough Extrusion and Shaping: The dough must be extruded and shaped properly; something achieved through using advanced extrusion technology having temperature /pressure sensors.This produces even sized pasta shapes leading to reduction of product variation.

- Drying Process: Drying stage is significant for high-quality paste.Automated full lines apply controlled drying chambers where parameters such as temperature/humidity are carefully observed to ensure that dryness is spread evenly across the mass without causing any cracks at all so that it does not lose its initial texture.

- Quality Control: Evenly cooked pastas make it possible for vision systems which are linked to the whole making process to detect malfunctions. In this way, a fault like having a pasta with cracks, the wrong sizes or change in color can be detected.

- Continuous Operation: Continuous operation is facilitated by fully automatic lines design hence less downtime which enhances productivity and maintains consistency in output of batches.

By automating these critical stages, fully automated pasta production lines deliver superior product quality and consistency, meeting the stringent demands of both consumers and industry standards.

How to Maintain Equipment for Uninterrupted Production

Efficient equipment maintenance is essential for avoiding interruptions in production and upholding high-quality standards within a completely automated pasta production line. Here are some important parts and practices necessary for maintaining the right condition:

- Regular Inspection and Cleaning: Carrying out regular inspections as well as cleaning extensively on all parts of an equipment ensures early detection of wearing out hence no sudden stoppages. Therefore, check that there’s no build-up or contaminants on any movable part or surfaces coming into contact.

- Lubrication: Using correct lubricants prevents friction and wear of bearings gears and other moving parts. From the manufacturer’s perspective use food grade lubricants which keep hygiene levels high as well as improving durability rates for these equipments.

- Spare Parts Inventory: Sensors; belts; motors should be kept in stores so that they can be replaced quickly thus minimizing downtime. The list must contain everything suggested by the maker including factors such as frequency at which they run-out.

- Performance Monitoring: It may involve using PLCs alongside integrated monitoring systems to keep track of a given line’s performance.Some parameters namely temperature, pressure,and velocity need constant attention whenever it comes to this.Automatic warning about deviations can assist you while taking appropriate measures at every moment before they become big problems.

- Calibration: The importance of regular calibration is measured using sensors as well as control systems during pasta processing where accuracy matters most.This guarantees product uniformity throughout the course so that it does not change in terms of quality and taste.

- Training Personnel: The operators and maintenance staff must be well educated on how to operate and maintain the equipment. Regular trainings rejuvenate technological transformation worldwide.

- Scheduled Shutdowns: Organized maintenance breakdowns make equipment inspection, deep cleaning, and servicing possible. This should be done during low production periods so as not to affect the running of the firm.

- Documentation: Any maintenance activity that takes place should be recorded in a detailed manner. This will help in determining the health of the equipment as well as when future repairs need to take place.

From Spaghetti to Macaroni: Versatility of the Pasta Production Line

Adapting the production line to different pasta shapes: short cut and long cut

Modifications and considerations are key in adapting a production line for different shapes of the pasta. For instance, short-cut pasta dough like penne or macaroni is extruded through dies of the desired shape that are then cut to size by rotating knives. This requires such parameters as precise control over extrusion speed and knife rotation so as to maintain uniformity in terms of sizes and shapes. By contrast, long-cut pasta such as spaghetti or fettuccine employs another set of parameters. The dough is extruded through long dies before being trimmed to an appropriate dimension, dried and typically wound on spools or sold straight or coiled if desired. Both these procedures demand careful adjustment of mixing, extrusion, drying and cutting parameters unique to each kind of pasta. These technical adjustments will facilitate smooth transitions between various forms of noodles when coupled with the right patterns on dies which help maintain consistency in both product quality and appearance.

The Science Behind Perfect Spaghetti And Macaroni

Perfect spaghetti or macaroni can be achieved by blending good ingredients with correct processing and technical parameters that ensure consistent taste and texture.

Ingredients

- Semolina Flour: For elasticity and toughness that are necessary for pasta making high quality semolina from durum wheat is essential.

- Water: Texture can vary according to water purity or hardness levels; hence for dough preparation it is always advisable to use soft water with low concentrations of minerals.

Mixing And Kneading:

- Hydration Ratio: Optimal dough consistency results from 30-35% semolina to water ratio.

- Kneading Time: Adequate gluten development occurs within this time frame; therefore knead for not more than ten minutes but at least eight minutes.

Extrusion:

- Extrusion Pressure: For short-cut pasta this ranges between 30-70 bar while it is 80-120 bar for long-cut pasta considering size or shape.

- Temperature Control: 50-60°C is the extrusion temperature range that should be kept to avoid over-heating and moisture loss.

Cutting:

- Knife Speed: Achieving uniformity requires approximately 100 cuts per minute for short-cut pasta.

- Length For Long-Cut Pasta: The typical length of spaghetti is usually between 20-25 inches after cutting.

Drying:

- Drying Temperature: Initial drying at 50-60°C within one to two hours followed by final drying at 40-50°C bringing down the moisture content below12%.

- Drying Time: Depending on shape and thickness of the pasta, this may take between twelve and thirty six hours.

Following these technical parameters ensures that both spaghetti and macaroni retain their desired mouthfeel. The right control of temperature during extrusion as well as drying alongside appropriate hydration and kneading practices is important if one wants to end up with high quality noodles that cook uniformly and hold onto sauces better.

Customization Options In Macaroni And Spaghetti Making Machines

For any manufacturer who wishes to make pasta that meets specific consumer tastes and cooking standards, customization options in macaroni & spaghetti making machines are essential. Here are some areas where customization can be included;

Die Shapes And Sizes

- Variety of Dies: Custom dies can be chosen to produce a wide range of pasta shapes and sizes, from classic spaghetti and macaroni to more intricate shapes like fusilli or farfalle.

Material Choice: Dies made from Teflon or bronze, each imparting different textures to the pasta surface.

Control Systems

- Programmable Logic Controllers (PLCs): With advanced PLCs there can be very precise control of mixing, kneading, extrusion as well as drying processes.

- User Interfaces: These interfaces are highly customizable for ease in monitoring or manipulating parameters when necessary.

Kneading And Mixing Mechanisms

- Mixing Paddles: Different paddles are designed for optimizing dough mixing and hydration.

- Variable Speed Mixers: Speeds that can be adjusted to suit different consistencies of dough.

Extrusion Pressure and Temperature

- Pressure Adjustment: Machines can be set up to handle various extrusion pressures such as when making denser pasta shapes at higher pressures.

- Temperature Control: The systems that allow for accurate control of the extrusion temperature resulting in the preservation of different pasta types.

Cutting Mechanisms

- Adjustable Knife Speed: Speeds that may be programmed so as to facilitate consistent cutting of varied pasta shapes and sizes.

- Automated Cut Length: For instance, for long-cut pastas like spaghetti, there’s provision for length adjustment enabling culinary demands to be met through variations.

Drying Modules

- Temperature and Humidity Control: Drying processes may be adapted with specific temperature and humidity levels aligned with the given type of pasta and thickness involved.

- Modular Drying Chambers: Different drying times and conditions could be employed by customizable drying chambers towards optimizing the final moisture content.

Output Capacity

- Scalable Production: Smaller artisanal batches or larger industrial production are accommodated by machines which can scale independently for increased capacity requirements.

- Multi-line Systems: Different lines running simultaneously allow a variety of products to be produced on these pasta lines based on various specifications.

Here are some critical technical parameters with justifications:

- Hydration Ratio : It should have 30-35% water so as to have an optimum consistency in it and also gluten development in dough made from semolina flour.

- Kneading Time : This time needs 8-10 minutes because this will ensure proper gluten structure which is important for texture development during conditioning periods while using short gluten structured flours like semolina or durum wheat flour (Elbehery et al., 2007).

- Extrusion Pressure : The extrusion pressure for the short cut pasta should be 30-70 bar and 80-120 bar for long cut pasta. This ensures that the dough is correctly shaped without affecting its structure.

- Extrusion Temperature : Extrusion temperature should range from 50 to 60°C to ensure there is no overheating and maintain moisture levels.

- Knife Speed: Using knives at speeds between sixty to one hundred cuts per minute can make uniform short-cut pasta (Donsì et al., 2012).

- Drying Temperature and Time: It involves initial drying at 50-60°C for about one to two hours then final drying in between 40-50°C lasting for twelve to thirty six hours till the pasta has attained the required dryness level lowering moisture content below PCM water meter showed below twelve percent.

By integrating these customizable features, pasta making machines can be fine-tuned to produce high-quality pasta that meets specific requirements and maintains consistency in texture and taste.

The Extruder Machine: Heart of the Macaroni Making Process

Some Vital Characteristics of a High-Quality Extruder for Pasta and Macaroni

Sturdy Build:

- Material: Stainless steel is responsible for its long life, corrosion resistance, and hygiene.

- Construction: Heavy duty assembled to resist continuous operation and high pressure.

Precise Engineering:

- Screw Design: Tailored for homogenous extrusion and shorten the kneading time.

- Barrel Lining: Alloy material used for this purpose is excellent at resisting wear over an extended period.

Modular Design:

- Pasta Varieties Produced by Interchangeable Components : Easily interchangeable dies and screws being fitted in order to make varied pasta shapes.

- Scalability:It may include expanding current production units to cater for increased production levels.

Energy Efficiency:

- Prevents from loosing heat energy inside insulated Barrels

- The Variable Frequency Drives (VFDs) that adjust motor speed are meant to save on power consumption

Safety Features:

- Providing Immediate Shutdown Facilities via Emergency Stop Button when Accidents Occur

- Safety Guards covering Moving Parts thereby preventing Operators from Injuries as they work with them

Hygienic Design:

- A Quick Dismantling Process & Smooth Surfaces Support Reduced Down Time & Enhanced Cleaning Methods

- Sanitation Compliance based on Food Safety Standards applied within the Industry

Pasta Quality Consistency:

- Keeping the Uniform Extrusion Pressure results into Constant Dough Texture & Uniform Pasta Quality

- Temperature Control in order not to allow degradation & protect dough moisture during the process itself

Innovative Technology:

- Vacuum Extrusion in which air bubbles removed yields dense pasta products with equal density all through it;

- Sensor Integration which monitors such key variables as pressure or temperature on real-time basis.

Support and Maintenance:

- Technical Support helps to deal with Equipment Problems Faster

- Availability of Spare Parts which can help in keeping the machine up and running without any long service interruption

Relevant Technical Parameters & Reasons for Using Them

Extrusion Pressure:

- Short-cut Pasta: 30-70 bar

- Long-cut Pasta: 80-120 bar

- Justification: Ensures that dough structure is not compromised while being shaped.

- Extrusion Temperature:

- Range: 50-60°C

- Justification: This range prevents overheating and maintains moisture in the product.

- Kneading Time:

- Duration: 8-10 minutes

- Justification: This is crucial for achieving desirable gluten structure of pasta textures.

- Knife Speed:

- Rate: 60-100 cuts per minute

In order to ensure optimal pasta texture, extruder settings should be optimized by carefully adjusting a number of parameters. The essential factors are as follows:

- Temperature Control: Temperature is important and must be maintained at an optimum range for extrusion to take place. Dough consistency directly affects the texture of the pasta.

- Moisture Content: It is crucial to manage accurate water content in the dough. Properly hydrating the dough prevents it from becoming too sticky or too dry which can affect how the finished product feels when chewed.

- Screw Speed: Changing screw speed has a great impact on pasta density and texture. Slower speeds make it denser while faster ones create lighter products.

- Die Design: Shaping and surface finish of pasta are influenced by design and status of extrusion dies. In order to maintain quality consistency, it is necessary to ensure that die is clean and free from any obstructions.

- Pressure Regulation: The firmness and bite of pasta are influenced by pressure during extrusion. With consistent pressure, uniformity of texture can be achieved throughout a batch.

Through these minor adjustments, manufacturers can manufacture superior quality pastas with better textures hence ensuring customer satisfaction and excellence in their product lines.

Embracing Innovation: Next-Generation Macaroni Pasta Machines

Exploring Latest Developments in Pasta Machinery and Equipment

There is no doubt that the sector is being transformed with innovation. Advanced automation technologies are found in modern pasta machines, which not only increase efficiency of production but also ensure uniformity of quality as well. Innovations such as fine temperature and moisture control systems, advanced extrusion techniques and improved designs for dies have pushed boundaries that were there previously in making pasta. These developments make it possible to produce a better texture, more nutritive value, different shapes and sizes of pasta. Moreover, real-time monitoring can be facilitated by integrating smart technology with IoT, thus reducing the waste stream and optimizing factory performance. By embracing these cutting-edge technologies, manufacturers can stay ahead in competitive market delivering superior products to their customers.

Future of Pasta and Macaroni Making: Smartness + Sustainability

In the future world of pasta or macaroni production will involve smartness combined with sustainability. From my research across the top websites it’s clear sustainable practices like using eco-friendly packaging materials are becoming more important than ever before while working towards a zero carbon footprint World at large—basically some authors really know what they are writing about here (pasta makers). This ensures efficient operations in terms of reduced wastage as well as high productivity thereby optimizing how much is produced., so combining all three aspects means we can provide goods at lower prices without sacrificing quality while at same time meeting growing customer demands for greener manufacturing methods. Therefore incorporating these kinds of intelligent sustainable ideas is necessary if one wants to stay competitive enough to satisfy needs from customers within this industry.

Integrating IoT + AI into Pasta Production for Increased Efficiency

It’s evident that integration of IoT in pasta production has numerous benefits significant on enhancing efficiency. IoT devices allow live monitoring from when ingredients start mixing through extrusion process up to drying stage; providing instant adjustments that minimize wastage during manufacture as well as help in achieving consistent quality. AI driven systems enhance predictive maintenance, thereby minimizing downtime and prolonging machinery life cycle. Furthermore, these technologies have the ability to optimize resource allocation hence ensuring that operations are energy efficient and cutting down on carbon footprints at large. Hence, by leveraging these technologies, manufacturers can significantly improve productivity; reduce costs of operation and produce superior product.

Reference sources

-

Loyal Pasta Machine Blog: Unlock the Secrets of the Automatic Macaroni Production Line

- This guide offers an in-depth overview of the automatic macaroni production process, making it ideal for those looking to understand the intricacies of macaroni manufacturing.

-

Basic Knowledge of Automatic Macaroni Pasta Production Line

- This document covers the fundamental aspects of operating a fully automated macaroni production line, including the stages and the technology involved.

- Read More

-

YouTube: Farfalle Macaroni Production Line

- A professional video explaining the processes and machinery involved in a fully automated vacuum pasta processing line, which includes macaroni production.

- Watch Here

Frequently Asked Questions (FAQs)

Q: What does the automatic macaroni production line entail?

A: In cooking, drying, and packaging of pasta, a series of advanced production line equipments are included in the automatic macaroni production line. These include pasta macaroni making machines, dryers, coolers and packaging units. The dough is mixed first for shaping through a macaroni pasta extruder production line; thereafter it is dried and cooled before packaging.

Q: How does a macaroni making machine work?

A: A macaroni making machine usually works by taking the raw materials usually flour and water mixture and then this is extruded via a mold to make shapes such as noodles, spaghetti or macaroni. The machine also cuts the extruded pasta into desired lengths. It’s an automated process that is efficient therefore suitable for industrial pasta making.

Q: What types of pasta can be produced on a pasta macaroni production line?

A: So many kinds are made along with traditional ones like Italian short pasta like penne as well as long cut pastas like fettuccine and spaghetti which equally depend on the shaping moulds in existence. Freshness is adjustable to make special sorts of pasta with this equipment.

Q: Can the same production line produce both pasta macaroni and spaghetti?

A: Yes, this can be done by adjusting properly & changing molds between them; hence one can change from producing one type of food to another using the same processing line automatically. Thus, it enhances product variability hence effectiveness by manufacturing diverse varieties from just one apparatus.

Q: What are the benefits of using an industrial pasta making machine?

A: Among advantages associated with utilization includes increased productivity efficiency, uniformity in the final products made, adaptability on what kind/type of paste they may want to produce/ come up with as well as minimized labor force costs. For large-scale productions, automatic controls and monitoring see to it that pasta meets stringent requirements for quality.

Q: How important is the pasta processing line in ensuring the quality of macaroni pasta production?

A: The pasta processing line is essential to ensure the quality of macaroni pasta production as it controls every stage from mixing and extrusion, drying to packaging. Hence, each piece of pasta is made with due sophistication thereby leading to excellent final product’s texture, taste, and look.