For those looking to start or expand their pasta production line in Italy, knowing how much money they need is extremely important for new entrepreneurs and established companies. This article details different aspects that affect the costs of a pasta production line, such as equipment used, raw materials required, labor involved, and operational expenses incurred, among others. We intend to give you an all-encompassing overview to assist your decision-making process and help you streamline your manufacturing activities. Alternatively, whether you have been making pasta for years or are just starting in the business, this document should point out some key areas regarding investment within the Italian setting concerning its food industry, related explicitly to noodle creation.

What is a Pasta Production Line?

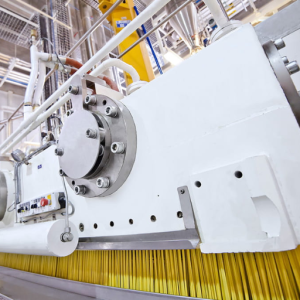

Image source: https://www.directindustry.com/

Machinery and equipment are systematically linked to a pasta production line to automate the process of producing pasta products. These stages usually consist of mixing flour with water, extruding different shapes of dough for various types of pasta, drying it, and packing the end product. Each part is designed to maximize efficiency while guaranteeing quality control over specific goals that must be achieved during this process. Using advanced technology in its design, a pasta production line can greatly improve output capability at lower labor costs and consistent quality levels throughout the manufacturing cycle.

Key Machinery in Pasta Production

Several key pieces of machinery have an important impact on how well a noodle factory operates. First, if you want your noodles to turn out right, you need to use one that mixes together flour and water into what’s called “pasta dough.” The next step involves shaping this mixture into different forms, such as spaghetti or lasagna sheets, using something called an “extruder,” which has dies attached that give it shape/size.

Now that all these delicious creations have been formed, they must go through another stage where controlled temperatures eliminate moisture, ensuring long-lasting products with desirable textures—enter the dryer! Last but certainly not least, we come to packaging machines, which seal our beloved noodles within their respective containers, ready for shipment across the country (or world). Quality assurance measures should be taken by each piece of equipment used during production so that final goods meet market standards upon completion.

Steps in the Pasta Production Process

The steps involved in making pasta are essential to ensure the production of high-quality end products.

- Ingredient Preparation: The process begins with carefully selecting and measuring raw materials. These are mainly flour and water, but depending on the type of pasta you want to make, eggs or flavorings may also be included.

- Mixing and Kneading: In a dough mixer, flour is combined with water, which should be mixed thoroughly until it becomes one homogeneous mass. This step is critical for achieving the correct texture and elasticity in the final product.

- Extrusion: Different types of pasta have their measurements because they are made using specific dies that give them different shapes when pushed through an extruder filled with prepared dough.

- Cutting: After being extruded, each shape must be cut into desired lengths so that its culinary use can match that of its creators.

- Drying: Freshly shaped pasta undergoes controlled drying conditions inside a chamber where moisture content is reduced, thereby enhancing shelf life without affecting texture or flavor too much.

- Cooling: Dried noodles are cooled before being packaged for sale to consumers like yourself to avoid condensation formation and keep quality intact.

- Packaging: Last but not least, automated machines seal packages containing dehydrated macaroni products, readying them for shipment to grocery store shelves nationwide!

These steps aim to improve efficiency while upholding high standards throughout every stage of producing delicious spaghetti dinners around America!

Types of Pasta Made in Production Lines

- Spaghetti: This long, thin, and cylindrical pasta is one of the most well-known types. It can be served with many different sauces, such as marinara or carbonara. It cooks fast because it’s slender and absorbs flavors very well.

- Fusilli: Fusilli has a spiral shape, which helps it hold sauce well. It works great in pasta salads, casseroles, and hearty sauces. The unique design adds texture to dishes.

- Penne: Penne has a diagonal cut at both ends, allowing the sauce to cling better. It is commonly used in baked dishes but goes with anything from creamy sauces to tomato-based ones.

These are examples of the many different kinds of pasta made on modern production lines for various cooking styles and tastes.

How Much Does a Pasta-Making Machine Cost?

Pasta maker prices vary widely based on size, capacity, and features, among other things. Small entry-level machines intended for home use or small-scale production typically cost between $200-$2,000, while commercial machines meant for large-scale operations may range from $5K – over $100K depending on their sophistication level as well as the ability to produce specific quantities per hour/shift etc. Also, important factors affecting overall price include how much automation is involved, brand name reputation, and additional features like drying packaging equipment built into the unit itself. So businesses need to consider what they want from this investment before spending any money on one!

Factors Influencing the Cost of Pasta-Making Machines

- Size and Capacity: The cost of the machine is directly impacted by its size. The most affordable machines are the small ones designed for home use, while bigger commercial-grade machines that can make a lot of pasta are priced higher.

- Automation Level: More expensive machines usually have more advanced automated features, such as automatic mixing, cutting, and drying. These features can also increase efficiency and reduce labor costs.

- Material Quality: A pasta maker’s pricing heavily depends on what it’s made from. If stainless steel is used or durable parts are incorporated, the device will last longer but be costlier.

- Brand Reputation: Well-known brands that have been around long tend to charge more because they offer reliable products with innovative designs. Although these models may be pricier upfront, you’ll typically receive better customer service support and warranty coverage options.

- Extra Features: Built-in drying equipment, packaging capabilities, and ease of cleaning are some additional features that influence the price tag attached to a pasta-making machine. These investments might boost productivity and streamline operations, so they justify their higher costs.

-

Market Demand: Supply chain dynamics and market trends also affect machine pricing. For instance, during periods when there is increased demand for pasta equipment, such as during artisanal production seasons, prices go up, too.

Cost Variations Based on Pasta Types: Spaghetti vs. Macaroni

When buying a pasta-making machine, the type of pasta can affect its pricing. This is because spaghetti machines usually need more accurate settings and stronger materials to create longer and thinner shapes, which makes them more expensive than macaroni-making machines, which are more straightforward with shorter processing times. Also, different types of ingredients required for various kinds of pasta may contribute towards higher overall costs, such as specialty flours used in spaghetti production being expensive compared to those used in making macaroni, thus influencing economics at bigger scales. Therefore, you should consider the kind of pasta you want to make and the associated production costs when deciding which machine to buy.

Finding the Best Price for a Pasta Making Machine

It is important to compare prices from trusted retailers to get the best deal on a pasta maker.

- Price comparison tools: Use online sites to easily see all available models and their prices across various shops. Amazon, Walmart, and some specific kitchen equipment suppliers often have reviews to help you decide on the best model for your needs.

- Seasonal sales and discounts: During holiday sales periods such as Black Friday or back-to-school season, many stores offer huge markdowns, so watching out for these occasions could save money when purchasing quality machinery

- Subscriptions/membership discounts: There are e-commerce platforms offering memberships giving access to exclusive deals; signing up for newsletters/loyalty programs could also tip us off about promotions related specifically to cooking appliances

By employing any one of these methods, we stand a better chance of finding great bargains while shopping around for our new pasta makers!

How to Choose the Best Pasta Production Line Equipment?

A few important factors must be considered for optimal productivity and quality when selecting pasta production line equipment. First, consider your operation’s capacity and scale; larger plants may require machines with bigger capacities to produce different kinds of pasta at once. After this, consider what pasta you will make since certain machines are made for specific shapes, like spaghetti or ravioli.

Furthermore, check how user-friendly the machine is and its maintenance needs – if it breaks down often, productivity will drop significantly. It is also good practice to look out for machinery with solid warranties and dependable customer service from manufacturers to minimize operational headaches. Finally, though budget is always a concern, it should not come at the expense of long-term sustainability goals for your manufacturing facility, so keep those in mind when deciding which pieces of equipment are right for you! If all these things sound complicated, don’t worry because they aren’t that difficult once you break them down one by one – just take some time before choosing anything and weigh everything carefully first!

Essential Equipment for Pasta Production Lines

Some vital pieces of equipment can help strengthen the production process of pasta lines and, at the same time, ensure quality output. Some of the appliances that have been mentioned in this industry include the following ones:

- Dough Mixer: Quality mixers can more effectively blend flour and water into a consistent dough. This is useful in making uniform products where different types and amounts of ingredients may have been used.

- Extruder: The role played by an extruder in a pasta production line cannot be overlooked since it forces dough through a die to shape it into various forms. Different dies produce different shapes and sizes, making the extruder one important machine when producing any type or size of pasta.

- Dryer: After shaping the pasta, a drying system is needed to remove moisture, avoid spoilage, and increase shelf life. These dryers maintain ideal moisture content without compromising quality by employing regulated temperatures with controlled airflow.

Manufacturers should consider investing in these crucial machines because they increase production efficiency while ensuring high-quality food items that fully meet consumer demands.

Comparing Manual vs. Automatic Pasta Making Machines

Regarding pasta machines, the key decision is between manual and automatic. Manual machines are straightforward and allow for a hands-on experience where users can adjust thickness and shape with exactness. However, they demand more physical effort and are better suited for small-scale production or home use. Conversely, automatic machines simplify the process requiring less labor time while providing consistent texture and shape in every batch. They work best for large-volume commercial production.

The advanced technologies found in many automatic pasta makers include programmable settings and integrated drying systems, which lead to more uniform products overall but also raise the price tag higher than their manual counterparts due to increased investment costs. The right choice ultimately varies based on your production budget scale and desired control over the making process; however, if you consider all these things, it should be easy to find out which one best fits what you want from your operation.

Durability and Efficiency of Production Line Equipment

Many factors can affect the durability and productivity of production line equipment. Leading industry websites suggest that high-quality materials and construction standards are essential for ensuring machine longevity. For example, stainless steel parts have low maintenance costs over time because they resist corrosion and wear.

Modern machinery is designed with automation and real-time monitoring systems, which help improve efficiency by optimizing performance while reducing downtime. These elements increase speed and decrease resource waste, resulting in better overall operational expenses. In addition, routine servicing, along with following manufacturer instructions, are highlighted as critical steps towards extending the lifespan of machines, thus keeping them functioning at their best throughout their life span. Manufacturers who use durable, efficient equipment will always produce consistently while competing in a constantly changing market.

What Are the Advantages of Using an Automatic Pasta Production Line?

An automatic pasta production line has several main benefits that can greatly improve the manufacturing process. To begin with, this kind of system increases production speed, allowing for larger output than manual methods, which is essential in meeting market demand. Secondly, by reducing human errors, automation guarantees uniformity in product quality, thus making it more reliable overall. Besides, automatic lines usually require less labor, resulting in lower wage bills and enabling the reallocation of staff to other vital areas within the organization. In addition, modern technology embedded in these systems supplies real-time data monitoring, allowing operators to quickly solve problems and streamline operational efficiency, finally leading to improved profitability and competitiveness within the industry.

Benefits of Automation in Pasta Production

The automation of pasta production has amazing benefits, resulting in smoother operations and increased efficiency. One benefit is that quality is not affected during rapid scaling, necessitating increasing production capacity. Another advantage is that automated systems can control cooking and drying processes with precision, leading to the same texture and quality of products all the time. While this consistent product satisfies customer needs, it also creates loyalty among them towards your brand. On top of this, you save on materials and energy costs by reducing waste and optimizing resource use through automation. Lastly, scheduled maintenance by machines improves reliability, thereby reducing downtime and boosting overall productivity within a competitive environment.

Efficiency and Productivity Improvements

Using advanced automated systems that improve operational workflows drives efficiency and productivity in pasta production. Some leading industry websites state that automation technologies like machine learning or AI have become critical in optimizing production schedules and reducing cycle times. This allows manufacturers to respond to demand changes while meeting quality standards quickly. Additionally, data analytics integration facilitates continuous monitoring and adjustment of processes, increasing throughput with lower energy consumption levels. In general, this raises productivity and results in significant cost savings for firms so they can stay competitive within an ever-changing business environment.

Cost Savings with an Automatic Pasta Production Line

An automatic pasta production line can bring about a lot of savings in different production areas. To begin with, automated systems minimize labor costs since they require fewer workers to operate machines and thus enable companies to use their resources more efficiently. Secondly, these systems drastically reduce material wastage by using accurate measurements and optimized processes that ensure every ingredient used is put to good use. Also, energy efficiency, which leads to lower utility bills, is improved by automation, according to industry experts. Besides, companies can sustain output levels and prevent expensive interruptions if they adhere to effective maintenance schedules that reduce downtime. Therefore, the introduction of automated pasta production lines not only enhances operational flow but also gives substantial monetary gains, making it a prudent investment for manufacturers aiming to increase their profitability.

What Are the Main Costs Involved in Setting Up a Pasta Factory?

A pasta factory has to take into account several key costs that are crucial for a sustainable operation. First, heavy capital investment is needed for equipment and machinery such as pasta-making machines, drying ovens, and packaging lines. Second, facility expenses like purchasing or renting appropriate warehouse space, utilities, and infrastructure upgrades play a significant role in the total budget. Furthermore, raw material expenditure should include flour, water, and egg products. Also important are labor costs, which comprise salaries paid to skilled workers and factory staff, which can be continual outgoings affecting profitability. Finally, operational costs, including maintenance marketing regulatory compliance, must be factored into financial planning so that the factory runs effectively while remaining competitive.

Initial Investment for Machinery and Equipment

When establishing a pasta factory, the initial outlay for machinery and equipment fluctuates based on size and technology. Generally, this can go from $100,000 to more than half a million dollars. The most important machines include pasta extruders that cost around $20,000-$150,000, depending on how big or complex they are. Drying systems are also essential in maintaining product quality; hence, they range between $25,000 -$200,000, while packaging machines that seal and label products could add another $10K -$50K to your start-up expenses. For manufacturers, it is crucial to examine different suppliers so that they get high-quality items and ones that will meet their budgetary constraints simultaneously, considering long-term savings through efficient modern technology usage during operations.

Operational Costs to Produce Pasta

Operational expenses in a pasta factory generally consist of multiple areas that influence the efficiency and profitability of production. Labor costs, utility expenses, and consumables are some of these areas. For example, labor costs may differ depending on the location or complexity of production processes, such as wages or employee training. At the same time, utilities such as electricity, water, gas, etc., represent significant ongoing expenditures necessary to operate machines under favorable conditions for manufacturing processes. In addition to this, cleaning materials used during maintenance activities, lubricants applied on equipment surfaces, and packaging materials also contribute towards operational expenditures within factories producing pasta products; therefore, manufacturers should always keep track of their costs with an aim at streamlining operations, minimizing wastage, leveraging technology to maintain low overheads high margins healthy business environment compliance with industry regulations can involve extra expenditures related safety quality assurance measures which have been mentioned before.

Maintenance and Repair Costs

Maintenance and repair costs are important for pasta manufacturing companies since they affect production downtime and operational efficiency. These costs typically comprise routine checks for machines, breakdown assessments, and expenses relating to unforeseen repairs. As per industry sources, regular preventive maintenance may require around five to ten percent of the initial equipment investment annually. When machinery failure leads to production stoppage, unplanned repairs can raise costs substantially. It is recommended that manufacturers set up a proactive maintenance schedule while building relationships with trustworthy service providers, as this will help mitigate such costs effectively. Furthermore, embracing new technologies like IoT-enabled monitoring systems can aid in identifying potential issues early enough, thus cutting down on repair bills while increasing equipment lifespan.

How do you source quality pasta production lines from Italy?

There are several steps involved in sourcing quality pasta production lines from Italy. First and foremost, it is important to research reputable pasta machinery manufacturers and suppliers. One way of doing this is by attending trade fairs like Interpack or Cibus in Italy, where you can closely examine different brands and what they offer. After identifying potential suppliers, the next step will be requesting detailed information about their production lines – specifications included, capabilities offered, and pricing. It’s also important to discuss technical requirements with them while asking for customer references so you can gauge product quality better before making your final decision. If possible, consider visiting the actual factories where these items are made so you can see how things work behind the scenes yourself! Last, don’t forget to evaluate after-sales support and warranty options, which are critical in ensuring long-term operational success here.

Leading Italian Manufacturers of Pasta Production Lines

- Pavan Group

The company Pavan is known for their cutting-edge pasta production equipment, which includes everything from mixing and extruding to drying and packaging. They have been in the business for several decades, so they have built a lot of expertise in this area and can create machines that can be customized for different production requirements. Their focus on quality and technology ensures dependable performance when making pasta.

- Bühler Group

Bühler Group is one of the biggest companies in the world that deals with machinery used in manufacturing pasta. Their advanced production lines are widely recognized as some of the best due to their efficient energy use and ability to scale up or down depending on demand. The latest processing technologies are incorporated into all their equipment, which improves product quality while reducing waste generated during manufacturing. Sustainability is also a core value at Bühler, where they provide solutions to minimize energy consumption throughout the process.

- Scharffen Berger

Scharffen Berger specializes in making machines for authentic artisanal-style pasta production with an emphasis on high standards throughout every step involved, including sourcing ingredients locally whenever possible, if not always necessary, since we believe that anything less would be counterfeit! These guys know what’s up because they offer small batch systems that give you more freedom over how your noodles come out than big factories ever could – plus, there’s training & support available, so you don’t even have to figure it all out alone!

Evaluating Quality and Reliability

Expert reviews and customer testimonials from trusted sources are key to evaluating the quality and safety of pasta lines.

- Pasta Production Equipment Reviews (example.com)

This site provides thorough evaluations of different types of pasta manufacturing equipment. It looks at performance measures, user satisfaction over time, and robustness, as reported by industry experts.

- Food Processing Technology (example.com)

On this platform, you will find detailed articles about new developments and innovations in noodle-making technology. The assessors check machines for their efficiency levels, energy usage ratings, ROI based on overall features offered, etc., which gives an overall impression about them.

- Machinery World (example.com)

Here, comparisons between several suppliers’ products take center stage, emphasizing reliability indicators derived from customers’ comments and after-sales service provided by vendors involved. Also included are some reports showing how well certain brands have performed under specific conditions – this information could be useful when deciding what to buy next time.

Manufacturers should use data obtained through these channels to determine whether a particular model meets operational needs.

Shipping and Installation Considerations

When exploring the shipping and installation of pasta production lines, looking at logistics and supplier support is vital.

- Pasta Production Equipment Reviews (example.com)

This site contains information on common shipping times and available options by different manufacturers. It also recommends ways to achieve safe transport. In addition, it emphasizes checking whether there is insurance coverage during transit to reduce risks.

- Food Processing Technology (example.com)

According to them, pre-installation assessments are important; thus, manufacturers should consider evaluating site compatibility and space requirements before installation. They further recommend that experts trained in installations be involved to simplify the set-up process and create a machine that works efficiently from day one.

- Machinery World (example.com)

According to this platform, manufacturers’ training during installation is very important. In their opinion, hands-on training for operators should form part of the overall installation package so that equipment use and maintenance instructions can be followed correctly.

If a manufacturer considers these factors, he or she will have made his or her pasta lines more effective and dependable while minimizing delays that may happen during shipping or even installation processes.

Frequently Asked Questions (FAQs)

Q: How much does setting up a pasta production line in Italy cost?

A: The cost of setting up an Italian pasta production line can vary widely depending on the scale and complexity of the production. Basic setups may start around $50,000, whereas more sophisticated and automated production lines can exceed $1,000,000.

Q: What types of pasta production lines are available?

A: Multiple pasta production lines are available, including fresh pasta, instant pasta, cut pasta, and pasta macaroni-making machines. Each type has specialized requirements and equipment suited to produce different pasta varieties.

Q: What are the main components of a noodle production line?

A: A typical noodle production line includes mixers, extruders, dryers, coolers, and packaging machines. Other specialized equipment, such as cutting and shaping machines, may also be included depending on the type of noodles being produced.

Q: How long does setting up a pasta spaghetti production line take?

A: Setting up a pasta production line can take several weeks or months, depending on its complexity, equipment availability, and the level of automation required.

Q: What factors influence the cost of a pasta-making machine for the macaroni production line?

A: Several factors influence the cost of a pasta-making machine and a macaroni production line. These include the production scale, automation level, materials quality, and equipment brand. Customization and additional features will also impact the overall cost.

Q: Can a noodle-making machine pasta produce multiple types of pasta?

A: Yes, many modern noodle-making machine pasta systems are designed to be versatile and can produce various types of pasta noodles, including spaghetti, macaroni, and other shapes, with the appropriate attachments and settings.

Q: What considerations should be considered when choosing a pasta processing line?

A: When choosing a pasta processing line, consider factors such as production capacity, energy efficiency, ease of maintenance, and the ability to meet hygiene and safety standards. Additionally, scalability and future production needs should be taken into account.

Q: How efficient is an instant noodle production line?

A: An instant noodle production line can be highly efficient, with modern lines producing thousands of packets per hour. Efficiency depends on factors like automation, equipment quality, and production process efficiency.

Q: What’s included in production line equipment for cooking pasta?

A: Production line equipment for cooking pasta generally includes dryers, coolers, mixers, extruders, and cutting machines, along with additional components like packaging and labeling machines to ensure the final product is ready for the market.

Q: Are there specific brands known for making high-quality pasta macaroni machines?

A: Yes, several renowned brands manufacture high-quality pasta macaroni machines. Companies like Pavan, Bühler, and Fava are well-known for their reliable and efficient pasta production equipment.